The Impact of Robotics on Manufacturing Automation

One significant advancement in robotics technology is the development of collaborative robots, or cobots. These robots are designed to work alongside humans in a shared workspace, contributing to increased efficiency and safety in various industries. Cobots are equipped with sensors and advanced programming, allowing them to adapt to dynamic environments and perform tasks that require precision and dexterity.

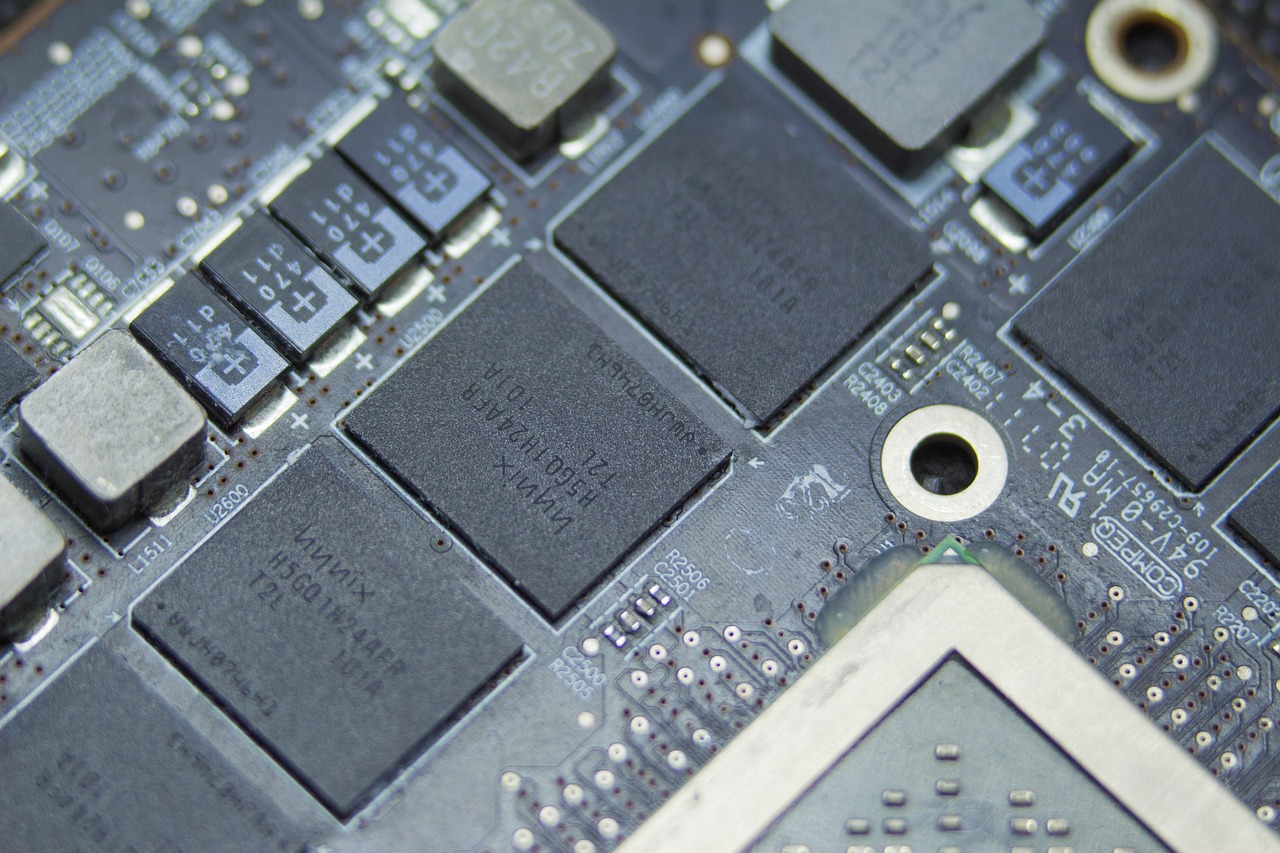

Another notable advancement is the integration of artificial intelligence (AI) in robotic systems. AI algorithms enable robots to learn from their experiences and improve their performance over time. This feature is particularly beneficial in tasks that involve decision-making and pattern recognition, making robots more versatile and capable of handling complex operations. As AI continues to evolve, robotic technology is expected to become even more sophisticated and specialized to meet the demands of modern industries.

Integration of Robotics in Manufacturing Processes

The integration of robotics in manufacturing processes has revolutionized the way industries operate. With robots taking over repetitive and dangerous tasks, companies can ensure higher efficiency and productivity in their production lines. By incorporating robots into various stages of manufacturing, businesses can streamline operations and achieve consistent quality in their products.

Moreover, the use of robotics in manufacturing processes has led to an increase in precision and accuracy. Robots are programmed to perform tasks with incredible accuracy, minimizing errors and reducing wastage in the production process. This not only improves the overall quality of the products but also helps in cost reduction for manufacturers. The integration of robotics has undoubtedly reshaped the manufacturing sector, paving the way for a more automated and efficient future.

What are some advancements in robotics technology that have enabled its integration in manufacturing processes?

Some advancements include improved sensors for enhanced precision, artificial intelligence for more autonomous decision-making, and collaborative robots designed to work alongside human workers.

How can robotics improve efficiency in manufacturing processes?

Robotics can automate repetitive tasks, increase production speed, reduce errors, and operate 24/7 without breaks, leading to higher efficiency in manufacturing processes.

What are the key benefits of integrating robotics in manufacturing processes?

The key benefits include increased productivity, improved quality control, reduced labor costs, enhanced workplace safety, and the ability to adapt to changing production demands more quickly.

Are there any challenges associated with integrating robotics in manufacturing processes?

Some challenges include high initial investment costs, the need for skilled technicians to operate and maintain the robots, potential job displacement, and the risk of cybersecurity threats.

How can companies ensure a successful integration of robotics in their manufacturing processes?

Companies can ensure success by conducting thorough research, investing in proper training for employees, collaborating with experienced robotics manufacturers, and continuously monitoring and optimizing the robotic systems.